Knit Open Width Compactor Machine for Textile Finishing

Introduction The machine is used for open width cotton fabric pre-shrinking process. At the beginning of overfeed, the c;

Basic Info.

| Model NO. | FSLS2400 |

| Universal Textile Testing Machine Type | Metal Detector |

| Textile Simulated Environmental Testing Machine Type | Drying Cabinet |

| Certification | CE, ISO9001: 2000 |

| Condition | New |

| Power | 27kw |

| Steam Consume | 150~200 |

| Power Cylinder | 54kw |

| Width | 2400mm |

| Speed | 5~35m/Min |

| Type | Fsls2400 Steam |

| Transport Package | FCL |

| Specification | 14540X4060X2970 |

| Trademark | FINESTART |

| Origin | Shandong Province, China |

| Production Capacity | 25units/Month |

Product Description

Introduction

The machine is used for open width cotton fabric pre-shrinking process.

At the beginning of overfeed, the cotton fiber will be processed by steaming to increase the humidity and plasticity. Then the fabric will be widened and pre-shrinked in order to reduce shrinkage and get a good soft feature.

Some fabric could be used directly after drying machine processing, and you can get a stable size, qualified shrinkage and soft effect. If the fabric couldn't reach the standard, you can repeat the processing step and obtain satisfactory result.

Based on different fabric width, we can provide the following machine models:

FSLS-2200mm/2400mm (standard)/2600 mm

Based on different heat sources, our machine adopt 3 heat methods:

Steam, Electricity + Oil, Circulation Conducting Oil

Our machine is mainly used for cotton and other natural fibers,

***The machine can NOT be used for synthetic fabrics.

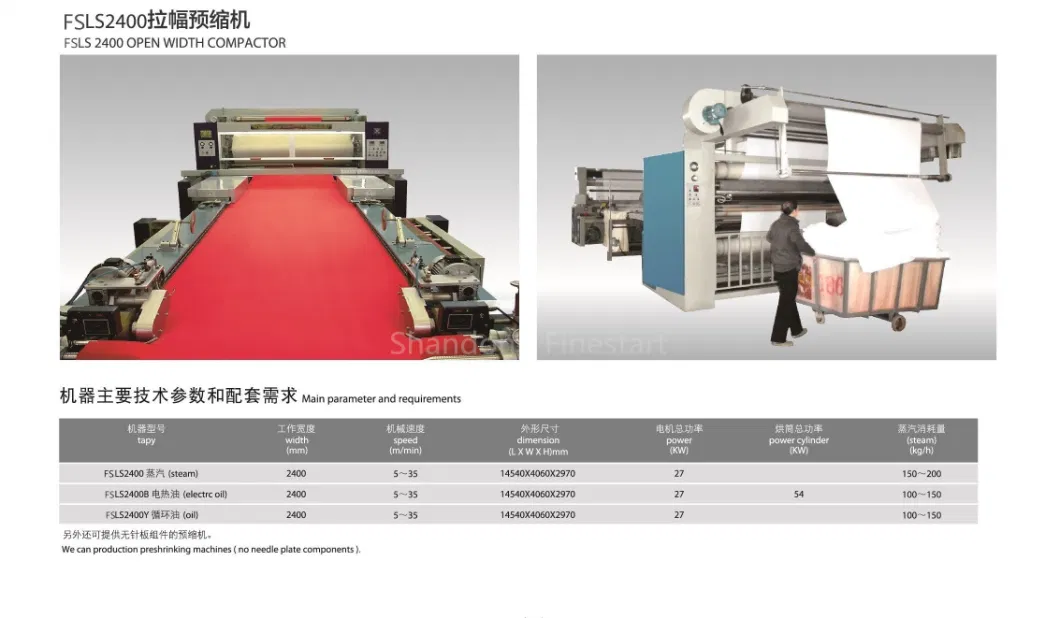

Design DrawingMain parameter and requirements

Basic Information

| Model | FSLS2400 |

| Name | Compactor |

| Application | Textile-finishing(shrinkage rate:4-5%) |

| Suitable Fabric | Open-witdh knitted Fabric,Pure cotton,wool,blended fabric(cotton content>65%) |

Technical Dates

| Felt Max. Width | 2400mm |

| Tentering Max. Width | 2600mm |

| Working Speed | 3-35m/min |

| Rail Type | Stainless Steel+ Graphite |

| Dimension | Approx. (14540*4100*3000mm)L*W*H |

| Weight | Approx. 12t |

| Compressed Air | 0.35-0.6MPa |

| Tentering Working Type | Horizontal Circulating Chain(Stainless Steel Pin Plate & Holder,Pitch:60mm) |

| Compacting Type | Felt Belt(Nomex)+ Hot Cylinder, Felt Belt Thickness:20-21mm |

Cost & Consumption

| heat source of Hot cylinder | ||||

| No | Item | Cylinder Max.Temp | Specification | Consumption |

| 1 | Electricity heat conduction Oil | 190ºC | Industrial Electricity | 25-54KW |

| Saturated Steam for Steam Box | ||||

| No | Item | Max.Temp | Specification | Consumption |

| 1 | Saturated Steam | 140ºC | 3-6Kg/cm² | 100-150kg/h |

| Electricity | ||||

| No | Item | Specification | Consumption | |

| 1 | Driving System | Main Motor etc | 21KW | |

Production Line

Finestart Family Products, Fine Start is Half Done.

Payment Terms

Payment Conditions: 30% down payment by T/T and the balance payment should be T/T or in irrevocable L/C at sight.

Delivery time:30-60 days from the date of receiving down payment. All payment should be received before delivery in China.

Welcome to visit our factory. Any questions and requirments,contact us now!

You may also like

Send inquiry

Send now